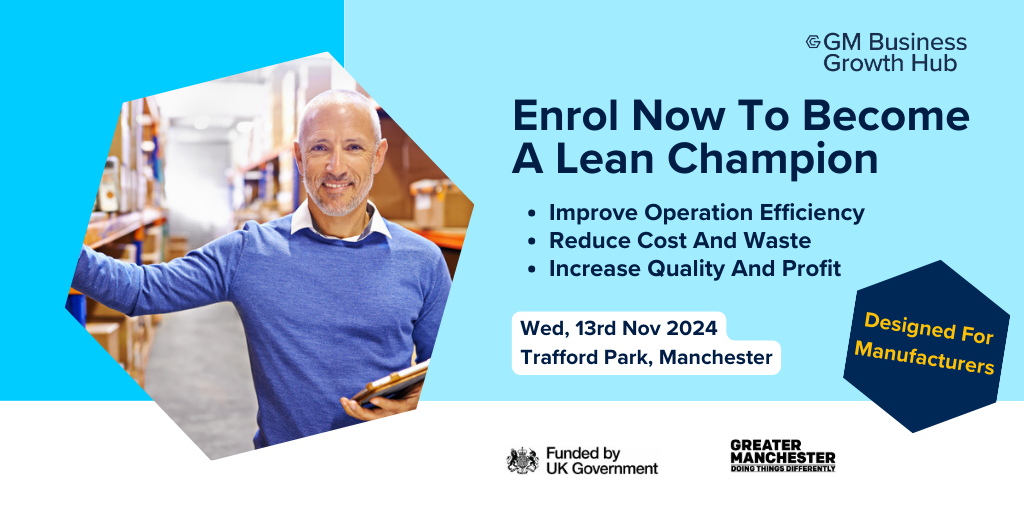

A Lean organisation is an organisation that is focused on maximising profit by understanding and giving the customer what they value 100% of the time. Join us for this one day practical workshop featuring factory simulations with our specialist Manufacturing Advisors (plus optional onsite follow-up support – all fully funded).

4 Reasons to Capitalise on Fully-funded Lean Champion Training

In this blog, our specialist Manufacturing Advisor Angela Robinson explains 4 reasons to capitalise on fully-funded Lean Champion training.

A Lean Organisation

Lean methods are a way of thinking that can be applied to your work and personal life. They are infectious. You will find yourself working in a team that is an efficient, more collaborative one. A Lean organisation is an organisation that is focused on maximising profit by understanding and giving the customer what they value 100% of the time.

A Lean Culture

A lean culture is a learning culture. A learning culture values problem solving and the standardisation of good practice. In this lean organisation problem solving must result in:

- Improved flow

- Reduced day to day variability

- Reduced waste

- Better information

- Standardised improvement

- Better Quality, Cost, Delivery than your competitors

- The identification of problems and how to solve them.

Become a Lean Champion

The Lean Champion exhibits the learning behaviours and possesses the appropriate tools and skills to enable positive change. It is the role of the Lean Champion to coach others, so these skills and behaviours become regular habits and routines throughout the organisation.

This one day practical workshop plus optional onsite follow-up support with a specialist Manufacturing Advisor (all fully funded) will provide the Lean Champion with:

The What

A process to identify, prioritise and implement continuous improvement opportunities.

The What Else

The tools to implement and sustain lean improvements and the critical success factors to make real change.

The How

A coaching routine through which they can engage others in lean activities, share the learning, teach the tools, and form the habits and routines.

Attendees will learn about tangible improvements in:

- Quality

- Processing time reduction

- Building stronger shop floor relationships

- Making working lives easier

- Business becoming more profitable.

For more information on how your data is stored please visit our privacy policy.

Sign-up to our newsletter

Insights, news, events and opportunities straight to your inbox.